Analysis Solution |

Analysis Modeler |

Field Model DescriptionAll the physical types to build Finite element models |

| Technical Article | ||

AbstractThis article describes the physical types that are defined for structural Analysis. We will describe the content of the physical dictionary provided with the Analysis package. The intent of this dictionary is to define a physic independent of the solver that is used. This philosophy as been put in place in order to be able to share the same physical model for a large number of solver. In this article, we will progress inside the field model by describing:

|

Those physical types are defined for the general management of the field model. They do not correspond to a physical definition.

| NONE | not a physical type definition. |

| GENERIC_CHARACTERISTIC | The explicit object associated is a CATAnalysisExplicitCharac without any physics. |

| GENERIC_ENTITY | The explicit object associated is a CATAnalysisExplicitEntity without any physics. |

| GENERIC_SET | The explicit object associated is a CATAnalysisExplicitSet without any physics. |

| CHARAC_COLLECTOR_POINTER | The corresponding explicit object is used to keep a link to a CATAnalysisCharacCollector. Such a kind of object will be used when the charac-collector is attach to it's parent. Internal use only. |

| ENTITY_COLLECTOR_POINTER | The corresponding explicit object is used to keep a link to a CATAnalysisEntityCollector. Such a kind of object will be used when an entity-collector is attach to it's parent. Internal use only. |

| EXPRESSION_POINTER | The corresponding explicit object is used to keep a link to a CATAnalysisExplicitExpression. Internal use only. |

The Generic physical types can be used if the definition of the physics is not defined in the mechanical file and it can be modified after by used the SetPhysicalType method. Note that all the explicit objects that will remain as "GENERIC" will not be streamed in the document.

The IMPORTED physical types can be used for import scenario.

The following physical types are defined in order to perform some data collect associated to an appropriate criterion.

| PHYSICAL_TYPE | useful to collect the physical types of all the entities aggregated in a set, or the physical types of the elements of the document. |

| USER_NUMBER | useful to collect the user number attributes of all the entities aggregated in a set, or the user number of the elements of the document. |

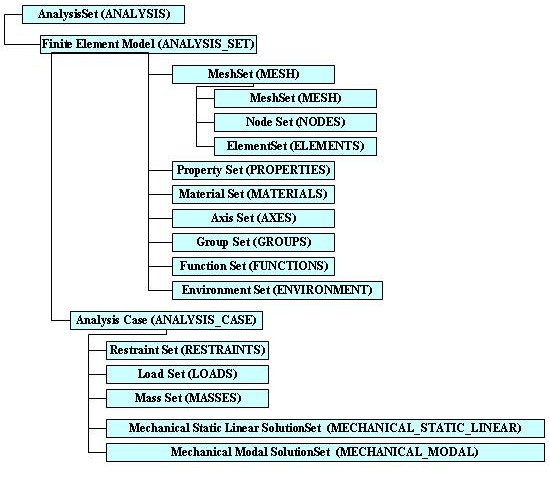

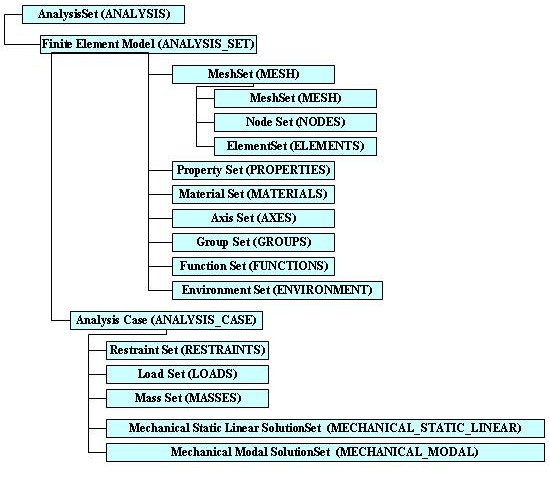

The field model sets structure is the finite element view (set up as the result view) of the feature tree. This is generated by the Dassault Systèmes implementation of the CATISamExplicitation Interface for AnalysisSet. It can be summarized by the following figure:

|

The figure shows the NLS names of the Sets (and associated physical type). For each set that is allowed to include others, find the list of allowed types. |

The Analysis Set and Finite Element Model sets are always created inside an Analysis document. they are respectively the field model view of the AnalysisManager and AnalysisModel features. The Analysis Set is the root object for accessing the model, and the Finite Element Model set is dedicated to manage the discretization (meshing data) and idealization (behavior of the part as physical properties). By default it contains a meshing set called Nodes and Elements, a property set, a material set, and an axis set.

This set is dedicated to receive meshing data inside the field model. It is the result of the MSHMeshSet (Nodes and Elements) feature. It can include a Node set and an Element set and (or) other MESH sets. This allow to design recursively meshing data.

This set is dedicated to receive nodal meshing data inside the field model. It includes the explicit nodes objects. The Explicit Node is linked to the Meshing node. The Explicit Node has a physical type "NODE". In some scenarios like assembly of analysis if the node is used to apply preprocessing data on node of external documents an explicit object with physical type "NODE_PROXY" is automatically created by the system.

This set is dedicated to receive finite element meshing data inside the field model. It includes the explicit element objects. The Explicit element is linked to the Meshing element. From this link, the explicit element can access all the geometrical data that are manage by the meshing framework. In addition, on the explicit entity, a physical type is defined that will define a physical behavior (For example, distinguish a bar and a beam that are represented by the same meshing connectivity) and some physical characteristics can be added. For additional information on the connectivity's, see Reference [1]. For additional information on the degrees of freedom definition, see Reference [2]. In some scenarios like assembly of analysis if the element is used to apply preprocessing data on element of external documents an explicit object with physical type "ELEMENT_PROXY" is automatically created by the system.

A characteristic of TRANSFORMATION_3D is used to define the cyclic periodicity transformation of a specific meshing specification.

The Explicit Element physical types are detailed here after.

These element types can be used without adding any characteristic. They provide the capability to have a non physical view of connectivity's inside the field model. They can be used for visualization purpose. No degree of freedom will be provided by those elements.

Here are gathered all the structural elements: The structural elements as opposed to the cinematic elements are element which represent an actual part of the structure. These elements have for instance a structural mass.

1D elements

Note: Unlike the cinematic element the 1D structural element should not be of null size. Indeed, computing for instance the mass of such element would not make sense.

The bar elements allow to define a rod with 2 or 3 nodes and 3 DOFs

per node: ![]() ,

,

![]() ,

,

![]()

No Characteristics can be defined these two elements.

The beam elements allow to define beams with 2 or 3 nodes and 6 DOFs per

node: ![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() .

.

Beams support three optional characteristics in order to define an orientation: ORIENTATION_VECTOR (a 3D vector), or ORIENTATION_POINT (3D coordinates) or ORIENTATION_NODE (a Reference to an explicit node). One of these three characteristics allows the definition of a local axis: The X axis is taken as being along the element while the Y axis tends to be towards the point or along the vector added.

Moreover, it is possible at the element level to optionally input:

The spring elements allow to define beams with 2 or 3 nodes and 6 DOFs per

node: ![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() .

.

2D elements

These Shell elements are defined with 6 DOF per node:

,

,

,

,

,

.

Note: In fact only 5 DOFs in the local element reference frame:

as for classic is inexistent and support the PROPERTY_SHELL_3D property.

Moreover two characteristics are optionally available on these four elements:

- The characteristic SURFACE_OFFSET allows the definition of an offset in meter normal to the element. This offset can be positive or negative; the normal is oriented in the classic way: If someone sees an element with the order of the nodes being clockwise, the normal is negative towards him.

- The characteristic MATERIAL_ANGLE allows the storage of the orientation of each element with respect to a user axis. This is only useful when using associated non-isotropic characteristic such as materials. See composite property for more details.

The plate elements

These elements, also none as membrane elements, are elements that only strain in their plane (traction, compression and shear).

No characteristic allowed on plate elements.

The shear panel elements

These elements, also none as membrane elements, are elements that only strain in their plane (only shear).

No characteristic allowed on shear elements.

No characteristic allowed on solid elements.

These elements as opposed to structural elements are not representation of actual parts. They are rather used to represent connections between parts or virtual parts. Note that a cinematic element has no mass. However additional mass can be added on the nodes of these elements. Note also that these elements unlike the structural elements can be of null size.

Note on that the three here above elements should model infinitely rigid connection or structures.

Note on the two here above MEAN elements normally used to model smooth connections.

The first node is linked to the center of gravity of the N-1other nodes according to rigid-body equations. This linkage process does not introduce any additional stiffness between the master nodes. The relations are computed as follow:

Notation:

is the vector containing the displacement at the master nodes.

is the vector containing the displacement at the center of gravity of the master nodes.

is the vector containing the displacement at the slave node.

is the inertia tensor.

is the [ (N-)1*6 , 6] matrix of the rigid bogy motion of the master nodes relative to the center of gravity. It depends on the coordinates of the center of gravity.

is the [6 , 6] matrix of the rigid-body motion of the slave node relative to the center of gravity. It depends on the coordinates of the center of gravity.

is the mass [18 , 18] matrix . It is a diagonal matrix whose coefficients are the weight of the master nodes (

).

are the translations at i node , and

are the rotations at i node.

The three here above elements are used to connect incompatible meshes with solid elements. The first node (slave node) is linked to its projection on the surface defined by the N other nodes (master nodes), according to the rigid-body equations (translations only). Then, the projected node is linked to the master nodes using the shape functions corresponding to the number of masters. This linkage process does not introduce any additional stiffness between the master nodes. The relations are obtained in the following way:

- Compute the projection of the slave. The surface on which this node is projected is defined by the shape function of:

- Triangular 3 Node Element, if it is a 4-Node JOIN (3 slave nodes)

- Quadrangular 4 Node Element, if it is a 5-Node JOIN (4 slave nodes)

- Triangular 6 Node Element, if it is a 7-Node JOIN (6 slave nodes).

- Quadrangular 8 Node Element, if it is a 9-Node JOIN.(8 slave nodes).

- Link the displacements of the projected node to those of the masters using the same Shape functions.

- Link the displacements of the slave to those of the projected node using rigid-body equations.

Other elements

This set is dedicated to receive finite element properties data inside the field model. It includes explicit entity objects with physical types compatible with PROPERTIES. The Explicit entities that manage this are defined with the following physical types:

This set is dedicated to build some hierarchy inside the model. It groups all kinds of external data applied on the idealization. It can include Boundaries, Loads and the solution set that will give access to all the physical data that can be computed by the solver.

This set is dedicated to boundaries data inside the field model. It includes explicit entity objects with physical types compatible with RESTRAINTS. The entities that represent the fixities are the following:

This set is dedicated to loading data inside the field model. It includes explicit entity objects with physical types compatible with LOADS. The explicit entities for representing loading condition are:

This set is dedicated to non structural masses data inside the field model. It includes explicit entity objects with physical types compatible with MASSES. The explicit entities for representing non structural masses are:

This set is dedicated to grouping definition inside the field model based on finite elements entities. It includes explicit entity objects with the following physical types.

All of them are designed with sub-entities that are typed with the position of the apply type.

- NODE_GROUP

- EDGE_GROUP

- FACE_GROUP

- ELEMENT_GROUP

This set is dedicated to retrieve and results associated to a modal analysis. It includes explicit characteristics objects (dedicated to global set parameters) and charac collectors objects. Under this kind of solution the list of allowed physical type is:

|

For each mode k, the following computation is done: |

|

Only the translational DOFs are taken into account for this calculation (so, the rotational DOFs are NOT considered). So, NT stands for the total number of translation DOFs. So, the formula says that the sum is taken of the amplitude values of the translational DOFs and that this sum is divided by the number of translational DOFs and the maximum value of the translational DOFs. Note that the value is always between 0 and 1. A mode is local when the value is close to zero. A mode is global when the value is approaching 1.

Glossary:??

Rigid contact bar element with 2 nodes, used to impose a minimal clearance between the nodes in the direction of the segment joining the initial positions of these nodes. The user imposes the maximum amount by which the clearance projected on this segment can be reduced (this parameter can also be interpreted as an initial clearance between nodes, supposing that they are allowed to eventually come in contact). Its use is recommended when some part of a structure may be brought into contact with some other part of the structure. Contact elements are then defined for pairs of nodes from the two parts.

| Version: 1 [June 2001] | Document created DRAFT VERSION |

| [1] | Analysis Modeler Overview , Connectivities |

| [2] | About Degrees of freedom. |

| [Top] | |

Copyright © 2004, Dassault Systèmes. All rights reserved.