Machining |

NC Review |

Dump of Tool Path Content CommandReading tool path |

| Use Case | ||

AbstractThis article discusses the CAAMaiDumpToolPathCommand use case: |

The main role of this use case is to show how to use the CAA2 methods to read data in a tool path.

CAAMaiDumpToolPathCommand is a use case of the CAAManufacturingItf.edu framework that illustrates ManufacturingInterfaces framework capabilities.

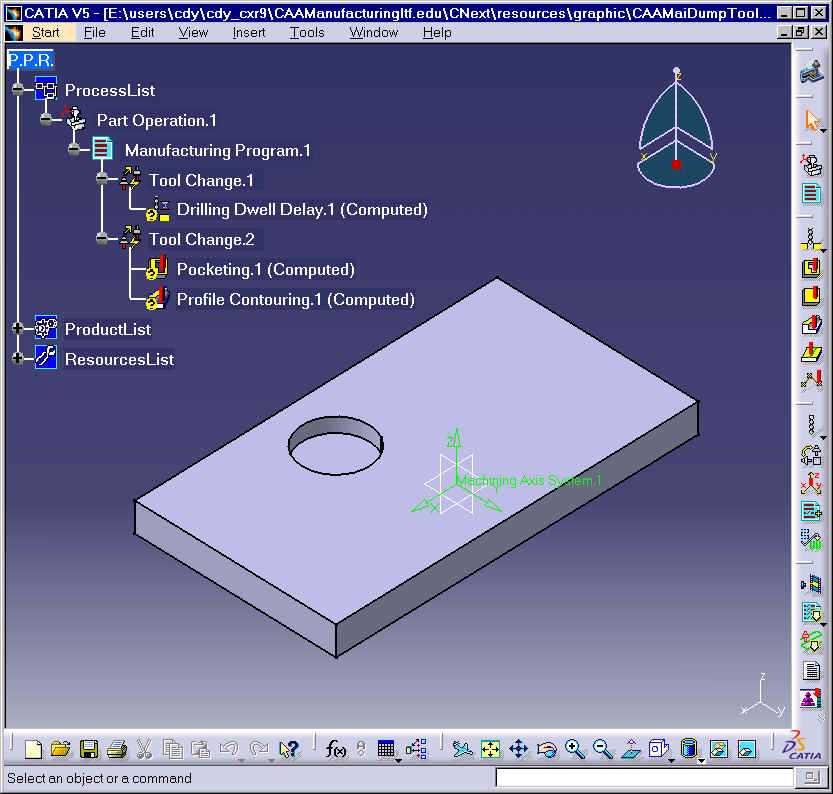

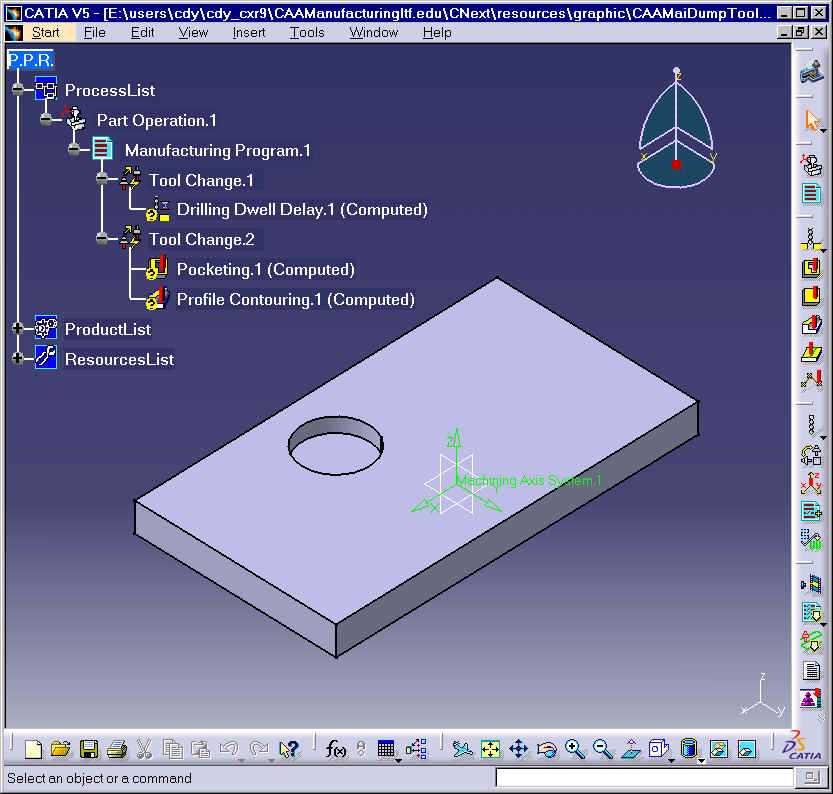

CAAMaiToolPathCustomization runs with the Process document shown on figure below that contains a "Drilling Dwell Delay" operation and a "Pocketing" operation.

Generating report on "Pocketing.1" operation

Generating report on "Drilling Dwell Delay.1" operation

Generating report on "Profile Contouring.1" operation

The tool path is a CATIMfgCompoundTraject object. It has one child, which is a CATIMfgTPMultipleMotion object.

The CATIMfgTPMultipleMotion object contains several "polylines" and circle arcs: all paths are machining paths with machining feedrate.

============================================================

=========== Dump of CATIMfgCompoundTraject object ==========

============================================================

Value of machining time (in minutes) 7.6112

Value of total time (in minutes) 7.6112

Number of linear motions 118

Number of circular motions 0

Tool Axis is fixed

Coordinates of tool axis in absolute axis system 0 0 1

Value of MachiningFeedrate 1000mm_mn

Value of ApproachFeedrate 300mm_mn

Value of RetractFeedrate 1mm_mn

Value of FinishingFeedrate 0.1mm_mn

Value of Spindle speed 70turn_mn

Name of tool or tool assembly T2 End Mill D 10

Value of corrector number 1

Start Point coordinates in absolute axis system 97.3438 2.9646 20

Start axis coordinates in absolute axis system 0 0 1

End Point coordinates in absolute axis system 14.3791 -36.3035 20

End axis coordinates in absolute axis system 0 0 1

------------------------------------------------------------

Child index 1 is a CATIMfgTPMultipleMotion object

------------------------------------------------------------

Number of tip points 536

Number of contact points 0

Number of contact normals 0

Number of tool axis 536

More than 100 tip points

Number of sub-motions 142

+++ Name of tool or tool assembly T2 End Mill D 10

+++ Sub-motion 1 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 1 2

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 2 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 3 4

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 3 is a circle

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 5 7

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Normal to the plane 0 0 1

++++++ Center of the circle arc 41.8731 -48.3068 20

++++++ Radius of the circle arc 72.6562 -48.3068 20

++++++ Angle of the circle arc -9.76176 -48.3068 20

++++++ Tangent at the start of the circle arc 0.765943 -0.642908 0

++++++ Tool corrector number 1

+++ Sub-motion 4 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 8 9

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 5 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 10 11

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 6 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 12 13

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 7 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 14 15

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 8 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 16 17

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 9 is a circle

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 18 22

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Normal to the plane 0 0 1

++++++ Center of the circle arc 41.8731 -48.3068 20

++++++ Radius of the circle arc 70 -48.3068 20

++++++ Angle of the circle arc -22.5416 -48.3068 20

++++++ Tangent at the start of the circle arc 0.832954 -0.553342 0

++++++ Tool corrector number 1

+++ Sub-motion 10 is a polyline

etc .....

In this case, the structure of the tool path is more complex.

The tool path is a CATIMfgCompoundTraject object which has 4 children:

The CATIMfgToolPathCycle object has one child, which is a CATIMfgTPMultipleMotion object:

============================================================

=========== Dump of CATIMfgCompoundTraject object ==========

============================================================

Value of machining time (in minutes) 0.0493333

Value of total time (in minutes) 0.0563333

Number of linear motions 12

Number of circular motions 0

Tool Axis is fixed

Coordinates of tool axis in absolute axis system 0 0 1

Value of MachiningFeedrate 1000mm_mn

Value of ApproachFeedrate 300mm_mn

Value of RetractFeedrate 1000mm_mn

Value of PlungeFeedrate 10mm_mn

Value of Spindle speed 70turn_mn

Name of tool or tool assembly T1 Drill D 10

Value of corrector number 1

Start Point coordinates in absolute axis system 150 60 31

Start axis coordinates in absolute axis system 0 0 1

End Point coordinates in absolute axis system -120 -90 31

End axis coordinates in absolute axis system 0 0 1

------------------------------------------------------------

Child index 1 is a CATIMfgTPMultipleMotion object

------------------------------------------------------------

Number of tip points 3

Number of contact points 0

Number of contact normals 0

Number of tool axis 0

Tip point number 1 150 60 31

Tip point number 2 150 60 31

Tip point number 3 150 60 21

Number of sub-motions 2

+++ Name of tool or tool assembly T1 Drill D 10

+++ Sub-motion 1 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 1 1

++++++ RAPID feedrate for the motion

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 2 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 2 3

++++++ Feedrate value 300mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

------------------------------------------------------------

Child index 2 is a CATIMfgTPMultipleMotion object

------------------------------------------------------------

Number of tip points 2

Number of contact points 0

Number of contact normals 0

Number of tool axis 0

Tip point number 1 150 60 21

Tip point number 2 150 60 21

Number of sub-motions 1

+++ Name of tool or tool assembly T1 Drill D 10

+++ Sub-motion 1 is a polyline

++++++ Type of path ApproachTraject

++++++ Index of Start and End tip points 1 2

++++++ RAPID feedrate for the motion

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

------------------------------------------------------------

Child index 3 is a CATIMfgToolPathCycle object

------------------------------------------------------------

Location point index 1 150 60 20

Location point index 2 150 -90 20

Location point index 3 -120 -90 20

NC_command evaluation CYCLE/DRILL, 0.000000, 1.000000

Value of machining time (in minutes) 0.006

Value of total time (in minutes) 0.013

Number of linear motions 8

Number of circular motions 0

Tool Axis is fixed

Coordinates of tool axis in absolute axis system 0 0 1

Value of MachiningFeedrate 1000mm_mn

Value of ApproachFeedrate 300mm_mn

Value of RetractFeedrate 1000mm_mn

Value of PlungeFeedrate 10mm_mn

Value of Spindle speed 70turn_mn

Name of tool or tool assembly T1 Drill D 10

Value of corrector number 1

Start Point coordinates in absolute axis system 150 60 21

Start axis coordinates in absolute axis system 0 0 1

End Point coordinates in absolute axis system -120 -90 21

End axis coordinates in absolute axis system 0 0 1

------------------------------------------------------------

Child index 1 is a CATIMfgTPMultipleMotion object

------------------------------------------------------------

Number of tip points 16

Number of contact points 0

Number of contact normals 0

Number of tool axis 0

Tip point number 1 150 60 21

Tip point number 2 150 60 20

Tip point number 3 150 60 20

Tip point number 4 150 60 21

Tip point number 5 150 60 21

Tip point number 6 150 -90 21

Tip point number 7 150 -90 21

Tip point number 8 150 -90 20

Tip point number 9 150 -90 20

Tip point number 10 150 -90 21

Tip point number 11 150 -90 21

Tip point number 12 -120 -90 21

Tip point number 13 -120 -90 21

Tip point number 14 -120 -90 20

Tip point number 15 -120 -90 20

Tip point number 16 -120 -90 21

Number of sub-motions 11

+++ Name of tool or tool assembly T1 Drill D 10

+++ Sub-motion 1 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 1 2

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 2 is a PP command

++++++ NC_Command value DELAY/ 2.000000,REV

+++ Sub-motion 3 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 3 4

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 4 is a polyline

++++++ Type of path LinkingTraject

++++++ Index of Start and End tip points 5 6

++++++ RAPID feedrate for the motion

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 5 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 7 8

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 6 is a PP command

++++++ NC_Command value DELAY/ 2.000000,REV

+++ Sub-motion 7 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 9 10

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 8 is a polyline

++++++ Type of path LinkingTraject

++++++ Index of Start and End tip points 11 12

++++++ RAPID feedrate for the motion

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 9 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 13 14

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 10 is a PP command

++++++ NC_Command value DELAY/ 2.000000,REV

+++ Sub-motion 11 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 15 16

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

------------------------------------------------------------

Child index 4 is a CATIMfgTPMultipleMotion object

------------------------------------------------------------

Number of tip points 2

Number of contact points 0

Number of contact normals 0

Number of tool axis 0

Tip point number 1 -120 -90 21

Tip point number 2 -120 -90 31

Number of sub-motions 1

+++ Name of tool or tool assembly T1 Drill D 10

+++ Sub-motion 1 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 1 2

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

Generating report on "Profile Contouring.1" operation

The tool path is a CATIMfgCompoundTraject object. It has one child, which is a CATIMfgTPMultipleMotionWithProfileData object.

A CATIMfgTPMultipleMotionWithProfileData object is a kind of CATIMfgTPMultipleMotion object on which it is possible to store cutter profile datas.

The CATIMfgTPMultipleMotionWithProfileData object contains several "polylines" to describe tip points: cutter profile motions linked to these "polylines" are either "polylines", or "circle arcs".

============================================================

=========== Dump of CATIMfgCompoundTraject object ==========

============================================================

Value of machining time (in minutes) 0.799783

Value of total time (in minutes) 0.799783

Number of linear motions 7

Number of circular motions 0

Tool Axis is fixed

Coordinates of tool axis in absolute axis system 0 0 1

Value of MachiningFeedrate 1000mm_mn

Value of ApproachFeedrate 300mm_mn

Value of RetractFeedrate 1mm_mn

Value of FinishingFeedrate 0.1mm_mn

Value of Spindle speed 70turn_mn

Name of tool or tool assembly T2 End Mill D 10

Value of corrector number 1

Start Point coordinates in absolute axis system -114.985 -85 20

Start axis coordinates in absolute axis system 0 0 1

End Point coordinates in absolute axis system -115 -84.9609 20

End axis coordinates in absolute axis system 0 0 1

------------------------------------------------------------

Child index 1 is a CATIMfgTPMultipleMotionWithProfileData object

------------------------------------------------------------

Number of tip points 14

Number of contact points 0

Number of contact normals 0

Number of tool axis 14

Tip point number 1 -114.985 -85 20

Tip point number 2 144.985 -85 20

Tip point number 3 144.985 -85 20

Tip point number 4 144.985 -85 20

Tip point number 5 145 -84.9609 20

Tip point number 6 145 54.9609 20

Tip point number 7 145 54.9609 20

Tip point number 8 145 54.9609 20

Tip point number 9 144.985 55 20

Tip point number 10 -114.985 55 20

Tip point number 11 -114.985 55 20

Tip point number 12 -114.985 55 20

Tip point number 13 -115 54.9609 20

Tip point number 14 -115 -84.9609 20

Number of sub-motions 7

+++ Name of tool or tool assembly T2 End Mill D 10

+++ Sub-motion 1 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 1 2

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 2 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 3 4

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 3 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 5 6

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 4 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 7 8

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 5 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 9 10

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 6 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 11 12

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

+++ Sub-motion 7 is a polyline

++++++ Type of path MachiningTraject

++++++ Index of Start and End tip points 13 14

++++++ Feedrate value 1000mm_mn

++++++ Ratio to apply on feedrate 1

++++++ Spindle value 70turn_mn

++++++ Ratio to apply on spindle 1

++++++ Normal rotation direction for the spindle

++++++ Fixed Tool Axis value 0 0 1

++++++ Tool corrector number 1

============================================================

+++ Dump of cutter profile datas

============================================================

+++ Cutter profile datas described by a polyline for sub-motion 1

+++ Cutter profile datas located on the right for sub-motion 1

Profile point number 1 -114.985 -90 20

Profile point number 2 144.985 -90 20

+++ Cutter profile datas described by a circle for sub-motion 2

+++ Cutter profile datas located on the right for sub-motion 2

Profile point number 1 144.985 -90 20

Profile point number 2 146.908 -89.613 20

Profile point number 3 148.536 -88.5195 20

Profile point number 4 149.622 -86.8858 20

Profile point number 5 150 -84.9609 20

+++ Cutter profile datas described by a polyline for sub-motion 3

+++ Cutter profile datas located on the right for sub-motion 3

Profile point number 1 150 -84.9609 20

Profile point number 2 150 54.9609 20

+++ Cutter profile datas described by a circle for sub-motion 4

+++ Cutter profile datas located on the right for sub-motion 4

Profile point number 1 150 54.9609 20

Profile point number 2 149.611 56.8795 20

Profile point number 3 148.524 58.5076 20

Profile point number 4 146.901 59.6023 20

Profile point number 5 144.985 60 20

+++ Cutter profile datas described by a polyline for sub-motion 5

+++ Cutter profile datas located on the right for sub-motion 5

Profile point number 1 144.985 60 20

Profile point number 2 -114.985 60 20

+++ Cutter profile datas described by a circle for sub-motion 6

+++ Cutter profile datas located on the right for sub-motion 6

Profile point number 1 -114.985 60 20

Profile point number 2 -116.908 59.613 20

Profile point number 3 -118.536 58.5195 20

Profile point number 4 -119.622 56.8858 20

Profile point number 5 -120 54.9609 20

+++ Cutter profile datas described by a polyline for sub-motion 7

+++ Cutter profile datas located on the right for sub-motion 7

Profile point number 1 -120 54.9609 20

Profile point number 2 -120 -84.9609 20

To launch CAAMaiDumpToolPathCommand, you will need to:

| Windows | InstallRootDirectory\CAADoc\CAAManufacturingItf.edu\CNext\resources\graphic\ |

| Unix | InstallRootDirectory/CAADoc/CAAManufacturingItf.edu/CNext/resources/graphic/ |

The CAAMaiDumpToolPathCommand use case is a C++ class named CAAMaiDumpToolPathCommand located in the CAAMaiDumpToolPathCommand.m module of the CAAManufacturingItf.edu framework:

| Windows | InstallRootDirectory\CAADoc\CAAManufacturingItf.edu\CAAMaiDumpToolPathCommand.m |

| Unix | InstallRootDirectory/CAADoc/CAAManufacturingItf.edu/CAAMaiDumpToolPathCommand.m |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed.

There are several logical steps in CAAMaiDumpToolPathCommand:

We now comment each of these steps by looking at the code.

//========================================================================

// Constructor

//========================================================================

CAAMaiDumpToolPathCommand::CAAMaiDumpToolPathCommand(CATString* argument)

:CATStateCommand ()

{

_File = NULL;

//===============================================

// Init of selection agent for activity selection

//===============================================

_ActAcq = new CATPathElementAgent("Act");

_ActAcq->SetElementType(CATIMfgActivity::ClassName());

_ActAcq->SetBehavior(CATDlgEngWithPrevaluation|CATDlgEngWithCSO);

}

//========================================================================

// Destructor

//========================================================================

CAAMaiDumpToolPathCommand::~CAAMaiDumpToolPathCommand()

{

//======================

// Close the report file

//======================

if (_File) fclose(_File);

_File = NULL;

if(_ActAcq) _ActAcq->RequestDelayedDestruction();

_ActAcq = NULL;

}

//========================================================================

// Build Graph

//========================================================================

void CAAMaiDumpToolPathCommand::BuildGraph()

{

if (NULL!=_ActAcq)

{

AddCSOClient(_ActAcq);

CATDialogState* InitState = GetInitialState("InitState");

if (NULL!=InitState)

{

InitState->AddDialogAgent(_ActAcq);

AddTransition (InitState, NULL, IsOutputSetCondition(_ActAcq),

Action((ActionMethod)& CAAMaiDumpToolPathCommand::DumpToolPath));

}

}

return;

}

|

This section of the source concerns the definition of the dialog agents, the dialog states, and the transitions:

DumpToolPath

is called on the selected operation.Refer to "Dialog Engine" documentation for further details.

...

//========================================================================

// DumpToolPath

//========================================================================

CATBoolean CAAMaiDumpToolPathCommand::DumpToolPath (void *)

{

//========================================

// Creates log file in temporary directory

//========================================

const char* cTemporaryDirectory = CATGetTempDirectory ();

char cNom_complet[CATMaxPathSize];

CATUnicodeString sFileName ("DumpToolPath.txt");

CATMakePath (cTemporaryDirectory,sFileName.ConvertToChar(),cNom_complet);

CATUnicodeString sNom_complet (cNom_complet);

CATLibStatus Status = CATFileAccess (sNom_complet,F_OK);

int i=0;

while (Status == CATLibSuccess && i<=100000)

{

//==========================================================

// if file "DumpToolPath.txt" exists in temporary directory,

// try to create "DumpToolPath-'i'.txt"

//==========================================================

i++;

CATUnicodeString Suffix;

Suffix.BuildFromNum (i);

Suffix = "-" + Suffix;

CATUnicodeString sFileName = "DumpToolPath" + Suffix + ".txt";

CATMakePath (cTemporaryDirectory,sFileName.ConvertToChar(),cNom_complet);

sNom_complet = (CATUnicodeString) cNom_complet;

Status = CATFileAccess (sNom_complet,F_OK);

}

if (Status == CATLibSuccess) return FALSE;

_File = fopen (sNom_complet.ConvertToChar(),"w");

//============================

// Retrieves selected activity

//============================

CATBaseUnknown_var SelectedObj = _ActAcq -> GetElementValue();

//=========================================

// Retrieves tool path on selected activity

// --> End if no tool path found

//=========================================

CATIMfgToolPathManagement_var Manage (SelectedObj);

if (NULL_var == Manage)

{

CATUnicodeString String (">>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> No Tool path on selected object");

WriteString (0,String);

return FALSE;

}

CATIMfgToolPath_var ToolPath;

Manage->GetToolPath (ToolPath);

if (NULL_var == ToolPath)

{

CATUnicodeString String (">>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> No Tool path on selected object");

WriteString (0,String);

return FALSE;

}

//====================================

// Loads PP Table for current activity

//====================================

CATIMfgCompoundTraject_var CompoundTraject (ToolPath);

if (NULL_var == CompoundTraject) return FALSE;

CompoundTraject->LoadsPPTable (SelectedObj);

//==================================================================

// Dump of the tool path

// Two cases are possible:

// The element is a CATIMfgToolPathCycle or a CATIMfgCompoundTraject

//==================================================================

CATIMfgToolPathCycle_var Cycle (ToolPath);

if (NULL_var != Cycle)

{

//=========================================

// The object is a CATIMfgToolPathCycle one

//=========================================

CATUnicodeString text1;

text1.Resize(60,'=');

WriteString (0,text1);

CATUnicodeString text2 ("=========== Dump of CATIMfgToolPathCycle object ============");

WriteString (0,text2);

WriteString (0,text1);

DumpCycle (0,Cycle);

}

else if (NULL_var != CompoundTraject)

{

//=========================================

// The object is a CATIMfgToolPathCycle one

//=========================================

CATUnicodeString text1;

text1.Resize(60,'=');

WriteString (0,text1);

CATUnicodeString text2 ("=========== Dump of CATIMfgCompoundTraject object ==========");

WriteString (0,text2);

WriteString (0,text1);

DumpCompoundTraject (0,CompoundTraject);

}

else return FALSE;

//===============

// End of command

//===============

RequestDelayedDestruction ();

return TRUE;

}

...

|

The method DumpToolPath is called when an operation is selected.

The name of the report file is DumpToolPath.txt in the temporary directory (by default, C:/Temp on NT, /tmp on UNIX): if the file already exists, a suffix is added (DumpToolPath-1.txt, DumpToolPath-2.txt, ....).

With the interface CATIMfgToolPathManagement and the method GetToolPath,

the tool path is read on the operation:

The tool path always implements the interface CATIMfgCompoundTraject (see below). The tool path can also implement the interface CATIMfgToolPathCycle (see below).

The method LoadsPPTable from the interface CATIMfgCompoundTraject

loads the PP table linked to the Part Operation containing the selected

activity: the call to this method is necessary to have a correct syntax

evaluation of nc_commands and nc_instructions.

If the tool path is a CATIMfgToolPathCycle object, the method DumpCycle

is called ; otherwise, the method DumpCompoundTraject is

called.

Dump of a CATIMfgCompoundTraject object

...

//====================

// DumpCompoundTraject

//====================

void CAAMaiDumpToolPathCommand::DumpCompoundTraject (int iLevel,

const CATIMfgCompoundTraject_var& iCompound)

{

if (NULL_var == iCompound) return;

//=========================================================================

// Retrieves machining time,total time, number of linear and circular motions

//=========================================================================

double MachiningTime,TotalTime;

long LinearMotions,CircularMotions;

if (iCompound->GetCharacteristics (MachiningTime,

TotalTime,LinearMotions,CircularMotions))

{

CATUnicodeString String1;

CATUnicodeString String2;

String2.BuildFromNum (MachiningTime);

String1 = "Value of machining time (in minutes)";

String1.Resize(60);

String1 = String1 + String2;

WriteString (iLevel,String1);

String2.BuildFromNum (TotalTime);

String1 = "Value of total time (in minutes)";

String1.Resize(60);

String1 = String1 + String2;

WriteString (iLevel,String1);

String2.BuildFromNum (LinearMotions);

String1 = "Number of linear motions";

String1.Resize(60);

String1 = String1 + String2;

WriteString (iLevel,String1);

String2.BuildFromNum (CircularMotions);

String1 = "Number of circular motions";

String1.Resize(60);

String1 = String1 + String2;

WriteString (iLevel,String1);

}

//====================================================================

// Retrieves axis guidance mode (Fixed,Variable)

//====================================================================

CATBoolean HasAToolAxis;

CATBoolean HasAFixedToolAxis;

CATMathVector Dummy;

if (iCompound->RetrievesFixedToolAxis (HasAToolAxis,HasAFixedToolAxis,Dummy))

{

CATUnicodeString String;

if (HasAToolAxis)

{

if (HasAFixedToolAxis)

String = "Tool Axis is fixed ";

else

String = "Tool Axis is variable ";

WriteString (iLevel,String);

}

}

//=======================================

// Retrieves value of reference tool axis

//=======================================

CATIMfgToolPathToolAxis_var ToolAxis;

if (iCompound->GetToolAxis(ToolAxis))

{

CATIMfgToolPathConstantToolAxis_var ConstantToolAxis (ToolAxis);

if (NULL_var != ConstantToolAxis)

{

CATMathVector ToolAxisValue;

if (ConstantToolAxis->GetToolAxis (ToolAxisValue))

{

CATUnicodeString ValueX,ValueY,ValueZ;

ValueX.BuildFromNum (ToolAxisValue.GetX());

ValueY.BuildFromNum (ToolAxisValue.GetY());

ValueZ.BuildFromNum (ToolAxisValue.GetZ());

CATUnicodeString String = "Coordinates of tool axis in absolute axis system";

String.Resize(60);

String = String + ValueX+" "+ValueY+" "+ValueZ;

WriteString (iLevel,String);

}

}

}

//==========================

// Retrieves feedrate values

//==========================

CATUnicodeString FeedrateType = TPMachiningFeedrate;

DumpFeedrate (iLevel,iCompound,FeedrateType);

FeedrateType = TPApproachFeedrate;

DumpFeedrate (iLevel,iCompound,FeedrateType);

FeedrateType = TPRetractFeedrate;

DumpFeedrate (iLevel,iCompound,FeedrateType);

FeedrateType = TPFinishingFeedrate;

DumpFeedrate (iLevel,iCompound,FeedrateType);

FeedrateType = TPChamferingFeedrate;

DumpFeedrate (iLevel,iCompound,FeedrateType);

FeedrateType = TPPlungeFeedrate;

DumpFeedrate (iLevel,iCompound,FeedrateType);

//==================================

// Retrieves the spindle speed value

//==================================

CATIMfgToolPathSpindle_var Spindle;

if (iCompound->GetSpindle (Spindle))

{

CATIMfgToolPathConstantSpindle_var ConstantSpindle (Spindle);

if (NULL_var != ConstantSpindle)

{

CATICkeParm_var SpindleValue;

if(ConstantSpindle->GetSpindle (SpindleValue))

{

if (NULL_var != SpindleValue)

{

CATUnicodeString String = "Value of Spindle speed";

String.Resize(60);

String = String+SpindleValue->Show();

WriteString (iLevel,String);

}

}

}

}

//====================================

// Retrieves the tool or tool assembly

//====================================

CATIMfgToolPathToolAssembly_var TPTA;

if (iCompound->GetToolAssembly (TPTA))

{

CATBaseUnknown_var ToolOrToolassembly;

if (TPTA->GetTool(ToolOrToolassembly))

{

CATIMfgResource_var spResource (ToolOrToolassembly);

if (NULL_var != spResource)

{

CATUnicodeString Name;

spResource->GetName(Name);

CATUnicodeString String = "Name of tool or tool assembly";

String.Resize(60);

String=String+Name;

WriteString (iLevel,String);

}

}

}

//====================================

// Retrieves the Tool Corrector Number

//====================================

int CorrectorNumber;

if (iCompound->GetCorrectorNumber (CorrectorNumber))

{

CATUnicodeString String;

String.BuildFromNum (CorrectorNumber);

CATUnicodeString String1 = "Value of corrector number";

String1.Resize(60);

String1 = String1 + String;

WriteString (iLevel,String1);

}

//===========================================

// Retrieves the start point of the tool path

//===========================================

CATMathPoint StartPoint;

CATMathVector StartVector;

if (iCompound->GetStartPoint (StartPoint,StartVector))

{

CATUnicodeString ValueX,ValueY,ValueZ;

ValueX.BuildFromNum (StartPoint.GetX());

ValueY.BuildFromNum (StartPoint.GetY());

ValueZ.BuildFromNum (StartPoint.GetZ());

CATUnicodeString String = "Start Point coordinates in absolute axis system";

String.Resize(60);

String=String+ValueX+" "+ValueY+" "+ValueZ+" ";

WriteString (iLevel,String);

ValueX.BuildFromNum (StartVector.GetX());

ValueY.BuildFromNum (StartVector.GetY());

ValueZ.BuildFromNum (StartVector.GetZ());

String = "Start axis coordinates in absolute axis system";

String.Resize(60);

String=String+ValueX+" "+ValueY+" "+ValueZ+" ";

WriteString (iLevel,String);

}

//=========================================

// Retrieves the end point of the tool path

//=========================================

CATMathPoint EndPoint;

CATMathVector EndVector;

if (iCompound->GetEndPoint (EndPoint,EndVector))

{

CATUnicodeString ValueX,ValueY,ValueZ;

ValueX.BuildFromNum (EndPoint.GetX());

ValueY.BuildFromNum (EndPoint.GetY());

ValueZ.BuildFromNum (EndPoint.GetZ());

CATUnicodeString String = "End Point coordinates in absolute axis system";

String.Resize(60);

String=String+ValueX+" "+ValueY+" "+ValueZ+" ";

WriteString (iLevel,String);

ValueX.BuildFromNum (EndVector.GetX());

ValueY.BuildFromNum (EndVector.GetY());

ValueZ.BuildFromNum (EndVector.GetZ());

String = "End axis coordinates in absolute axis system";

String.Resize(60);

String=String+ValueX+" "+ValueY+" "+ValueZ+" ";

WriteString (iLevel,String);

}

//===================

// Retrieves children

//===================

DumpChildren (iLevel,iCompound);

}

...

//=============

// DumpFeedrate

//=============

void CAAMaiDumpToolPathCommand::DumpFeedrate (int iLevel,

const CATIMfgCompoundTraject_var& iCompound,

CATUnicodeString& iFeedrateType)

{

if (NULL_var == iCompound) return;

CATIMfgToolPathFeedrate_var Feedrate;

if (iCompound->GetFeedrate (iFeedrateType,Feedrate))

{

CATIMfgToolPathConstantFeedrate_var ConstantFeedrate (Feedrate);

if (NULL_var != ConstantFeedrate)

{

CATICkeParm_var FeedrateValue;

if(ConstantFeedrate->GetFeedrate (FeedrateValue))

{

if (NULL_var != FeedrateValue)

{

CATUnicodeString String = "Value of "+iFeedrateType;

String.Resize(60);

String = String + FeedrateValue->Show();

WriteString (iLevel,String);

}

}

}

}

}

//=============

// DumpChildren

//=============

void CAAMaiDumpToolPathCommand::DumpChildren (int iLevel,

const CATIMfgCompoundTraject_var& iCompound)

{

if (NULL_var == iCompound) return;

iLevel++;

//================================================================

// Use of CATIMfgToolPathComponents interface to retrieve children

//================================================================

CATIMfgToolPathComponents_var Components (iCompound);

if (NULL_var == Components) return;

CATListValCATBaseUnknown_var* ListOfChildren = Components->GetAllElements ();

if (NULL!=ListOfChildren)

{

CATUnicodeString Index;

int size = ListOfChildren->Size();

CATUnicodeString text1;

text1.Resize(60,'-');

for (int i=1;i<=size;i++)

{

CATIMfgTPMultipleMotionWithProfileData_var MultipleMotionWithProfileData ((*ListOfChildren)[i]);

CATIMfgTPMultipleMotion_var MultipleMotion ((*ListOfChildren)[i]);

CATIMfgCompoundTraject_var CompoundTraject((*ListOfChildren)[i]);

CATIMfgToolPathCycle_var Cycle((*ListOfChildren)[i]);

CATUnicodeString String;

//=============================================================

// The child is a CATIMfgTPMultipleMotionWithProfileData object

//=============================================================

if (NULL_var != MultipleMotionWithProfileData)

{

WriteString (iLevel,text1);

Index.BuildFromNum (i);

String = "Child index "+Index+ " is a CATIMfgTPMultipleMotionWithProfileData object ";

WriteString (iLevel,String);

WriteString (iLevel,text1);

DumpMultipleMotionWithProfileData (iLevel,MultipleMotionWithProfileData);

}

//==============================================

// The child is a CATIMfgTPMultipleMotion object

//==============================================

if (NULL_var != MultipleMotion)

{

WriteString (iLevel,text1);

Index.BuildFromNum (i);

String = "Child index "+Index+ " is a CATIMfgTPMultipleMotion object ";

WriteString (iLevel,String);

WriteString (iLevel,text1);

DumpMultipleMotion (iLevel,MultipleMotion);

}

//===========================================

// The child is a CATIMfgToolPathCycle object

//===========================================

else if (NULL_var != Cycle)

{

WriteString (iLevel,text1);

Index.BuildFromNum (i);

String = "Child index "+Index+ " is a CATIMfgToolPathCycle object ";

WriteString (iLevel,String);

WriteString (iLevel,text1);

DumpCycle (iLevel,Cycle);

}

//======================================

// The child is a CATIMfgCompoundTraject

//======================================

else if (NULL_var != CompoundTraject)

{

WriteString (iLevel,text1);

Index.BuildFromNum (i);

String = "Child index "+Index+ " is a CATIMfgCompoundTraject object ";

WriteString (iLevel,String);

WriteString (iLevel,text1);

DumpCompoundTraject (iLevel,CompoundTraject);

}

//==================

// child not treated

//==================

else

{

CATISpecObject_var SpecObj ((*ListOfChildren)[i]);

if (NULL_var != SpecObj)

{

WriteString (iLevel,text1);

Index.BuildFromNum (i);

String = "!!!!!! Child index "+Index+ " which is a "

+SpecObj->GetName()+ " is not treated !!!!!";

WriteString (iLevel,String);

WriteString (iLevel,text1);

}

}

}

delete ListOfChildren;

ListOfChildren=NULL;

}

}

...

|

The CATIMfgCompoundTraject interface identifies the object stored on the operation to model the tool path.

It can own:

It can also have children:

The source shows the use of the following methods:

GetCharacteristics: computes or retrieves values of machining

time and total time (taking into account tool motions and values of

feedrates) . It retrieves also the total number of linear and circular

motionsRetrievesFixedToolAxis: analyzes if the tool axis of the tool

path is fixed or not, even if a tool axis is stored on each point of the

tool pathGetToolAxis: retrieves the value of the reference tool axisGetSpindle: retrieves the value of the reference spindle

speedGetFeedrate: retrieves the values of the reference feedratesGetToolAssembly: retrieves the tool or the tool assembly of

the operationGetCorrectorNumber: retrieves the tool corrector numberGetStartPoint: computes the start tip point (and its tool

axis) of the tool pathGetEndPoint: computes the end tip point (and its tool axis)

of the tool path.The interface CATIMfgToolPathComponents and the method GetAllElements

are used to retrieve the children of the CATIMfgCompoundTraject object.

Three cases are possible for each child:

DumpCycle

is called to dump its attributes and its childrenDumpCompoundTraject

is called to dump its attributes and its childrenDumpMultipleMotionWithProfileData is called to dump its

attributes.DumpMultipleMotion

is called to dump its attributes.

//==========

// DumpCycle

//==========

void CAAMaiDumpToolPathCommand::DumpCycle (int iLevel,

const CATIMfgToolPathCycle_var& iCycle)

{

if (NULL_var == iCycle) return;

//==========================

// Retrieves location points

//==========================

CATMathSetOfPoints Points;

if (iCycle->GetCycleLocationPoints (Points))

{

int size=Points.GetNumberOfPoints ();

if (size > 100)

{

CATUnicodeString String ("More than 100 location points ");

WriteString (iLevel,String);

}

else

{

CATMathPoint Pt;

CATUnicodeString ValueX,ValueY,ValueZ;

CATUnicodeString Index;

for (int i=1;i<=size;i++)

{

Pt = Points.GetPoint (i-1);

Index.BuildFromNum (i);

ValueX.BuildFromNum (Pt.GetX());

ValueY.BuildFromNum (Pt.GetY());

ValueZ.BuildFromNum (Pt.GetZ());

CATUnicodeString String = "Location point index ";

String = String + Index;

String.Resize(60);

String = String + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String);

}

}

}

//==================================================

// Retrieves axis (if they exist) on location points

//==================================================

CATMathSetOfVectors Vectors;

if (iCycle->GetCycleLocationAxis (Vectors))

{

int size=Vectors.GetNumberOfVectors ();

if (size > 100)

{

CATUnicodeString String ("More than 100 location axis ");

WriteString (iLevel,String);

}

else

{

CATMathVector Vec;

CATUnicodeString ValueX,ValueY,ValueZ;

CATUnicodeString Index;

for (int i=1;i<=size;i++)

{

Vec = Vectors.GetVector (i-1);

Index.BuildFromNum (i);

ValueX.BuildFromNum (Vec.GetX());

ValueY.BuildFromNum (Vec.GetY());

ValueZ.BuildFromNum (Vec.GetZ());

CATUnicodeString String = "Location axis index " + Index;

String.Resize(60);

String=String + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String);

}

}

}

//=======================================================================

// Retrieves syntax of the cycle

// --> UserSyntax OR

// --> Syntax evaluated from NC_Command or NC_Instruction of the PP Table

//=======================================================================

CATListValCATUnicodeString Liste;

if (iCycle->GetUserSyntax (Liste))

{

int size = Liste.Size();

for (int i=1;i<=size;i++)

{

CATUnicodeString String = "User syntax associated to the cycle";

String.Resize(60);

String = String + Liste[i];

WriteString (iLevel,String);

}

}

else if (iCycle->GetCommandEvaluation (Liste))

{

int size = Liste.Size();

for (int i=1;i<=size;i++)

{

CATUnicodeString String = "NC_command evaluation";

String.Resize(60);

String = String + Liste[i];

WriteString (iLevel,String);

}

}

//==========================================================================

// As a CATIMfgToolPathCycle object is also a CATIMfgCompoundTraject object,

// dump of its "CATIMfgCompoundTraject" attributes

//========================================================================

DumpCompoundTraject (iLevel,iCycle);

}

|

The CATIMfgToolPathCycle interface inherits from the CATIMfgCompoundTraject interface.

The CATIMfgToolPathCycle object is used to modelize machining cycles inside tool path:

The DumpCycle method shows the use of the following methods:

GetCycleLocationPoints: retrieves the points where to apply

the machining cycleGetCycleLocationAxis: retrieves the tool axis that can be

associated to the points where to apply the machining cycleGetCommandEvaluation: if the cycle is described by a

NC_Command or NC_Instruction, evaluates the syntax of this NC_Command or

NC_InstructionGetUserSyntax: if the cycle is described by a syntax entered

by the user, retrieves this syntax.In the sample, the DumpCompoundTraject method is called to dump

common attributes between CATIMfgToolPathCycle object and CATIMfgCompoundTraject

object.

//===================

// DumpMultipleMotion

//===================

void CAAMaiDumpToolPathCommand::DumpMultipleMotion (int iLevel,

const CATIMfgTPMultipleMotion_var& iMultipleMotion)

{

if (NULL_var == iMultipleMotion) return;

CATUnicodeString String1,String2;

CATUnicodeString ValueX,ValueY,ValueZ;

//===================================

// Retrieves the number of tip points

//===================================

int NumberOfTipPoints = iMultipleMotion->GetNumberOfTipPoints();

String1.BuildFromNum (NumberOfTipPoints);

String2="Number of tip points";

String2.Resize(60);

String2 = String2+String1;

WriteString (iLevel,String2);

//=======================================

// Retrieves the number of contact points

//=======================================

int NumberOfContactPoints = iMultipleMotion->GetNumberOfContactPoints();

String1.BuildFromNum (NumberOfContactPoints);

String2="Number of contact points";

String2.Resize(60);

String2 = String2+String1;

WriteString (iLevel,String2);

//========================================

// Retrieves the number of contact normals

//========================================

int NumberOfContactNormals = iMultipleMotion->GetNumberOfContactNormals();

String1.BuildFromNum (NumberOfContactNormals);

String2="Number of contact normals";

String2.Resize(60);

String2 = String2+String1;

WriteString (iLevel,String2);

//==================================

// Retrieves the number of tool axis

//==================================

int NumberOfToolAxis = iMultipleMotion->GetNumberOfToolAxisPoints();

String1.BuildFromNum (NumberOfToolAxis);

String2="Number of tool axis";

String2.Resize(60);

String2 = String2+String1;

WriteString (iLevel,String2);

//====================================

// Retrieves coordinates of tip points

//====================================

if (NumberOfTipPoints > 100)

{

String1="More than 100 tip points";

WriteString (iLevel,String1);

}

else

{

double x,y,z;

CATUnicodeString Index;

for (int i=1;i<=NumberOfTipPoints;i++)

{

if (iMultipleMotion->GetTipPoint (i,x,y,z))

{

ValueX.BuildFromNum (x);

ValueY.BuildFromNum (y);

ValueZ.BuildFromNum (z);

Index.BuildFromNum (i);

String1 = "Tip point number "+Index;

String1.Resize(60);

String2 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String2);

}

}

}

//================================

// Retrieves number of sub-motions

//================================

int NumberOfSubMotions;

if (iMultipleMotion->GetNumberOfSubTrajects (NumberOfSubMotions))

{

String1 = "Number of sub-motions ";

String1.Resize(60);

String2.BuildFromNum (NumberOfSubMotions);

String1 = String1 + String2;

WriteString (iLevel,String1);

}

//================================

// Retrieves Tool or Tool Assembly

//================================

CATBaseUnknown_var ToolOrToolAssembly;

if (iMultipleMotion->GetToolAssembly (ToolOrToolAssembly))

{

CATIMfgResource_var Resource (ToolOrToolAssembly);

if (NULL_var != Resource)

{

CATUnicodeString Name;

Resource->GetName(Name);

CATUnicodeString String = "+++ Name of tool or tool assembly";

String.Resize(60);

String=String+Name;

WriteString (iLevel,String);

}

}

//=========================================

// Retrieves information on each sub-motion

//=========================================

for (int i=1;i<=NumberOfSubMotions;i++)

{

CATUnicodeString Index;

//===================

// Type of sub-motion

//===================

CATIMfgTPMultipleMotion::SubTrajectType SubTrajectType;

if (iMultipleMotion->GetSubTrajectType (i,SubTrajectType))

{

Index.BuildFromNum (i);

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine)

{

CATUnicodeString String = "+++ Sub-motion "+Index+" is a polyline ";

WriteString (iLevel,String);

}

else if (SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

CATUnicodeString String = "+++ Sub-motion "+Index+" is a circle ";

WriteString (iLevel,String);

}

else if (SubTrajectType == CATIMfgTPMultipleMotion::UserSyntax)

{

CATUnicodeString String = "+++ Sub-motion "+Index+" is a user syntax ";

WriteString (iLevel,String);

}

else if (SubTrajectType == CATIMfgTPMultipleMotion::PPCommand)

{

CATUnicodeString String = "+++ Sub-motion "+Index+" is a PP command ";

WriteString (iLevel,String);

}

}

//=========================================================

// Path type (Machining, Linking, ....)

// --> For a polyline or a circle arc

// --> See CATMfgToolPathDefs for reference values

// (TPMachiningTraject, TPLinkingTraject, ...)

//=========================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

CATUnicodeString TrajectType;

if (iMultipleMotion->GetTrajectType (TrajectType,i))

{

String1 = "++++++ Type of path";

String1.Resize(60);

String1 = String1 + TrajectType;

WriteString (iLevel,String1);

}

}

//============================================================================

// Index of start point and end point in the list of tip points

// and, it they exist, in the list of tool path axis, contact points, etc ...

// --> For a polyline or a circle arc

// --> To get a tip point, use "GetTipPoint (i,x,y,z) with a value of "i"

// between index of start point and index of end point

//============================================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

int StartIndex,EndIndex;

if (iMultipleMotion->GetStartAndEndNumber (i,StartIndex,EndIndex))

{

ValueX.BuildFromNum (StartIndex);

ValueY.BuildFromNum (EndIndex);

String1 = "++++++ Index of Start and End tip points";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY;

WriteString (iLevel,String1);

}

}

//=====================================

// Retrieves feedrate of the sub-motion

// --> For a polyline or a circle arc

//=====================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

CATICkeParm_var FeedrateValue;

double Ratio;

CATUnicodeString Feedrate;

if (iMultipleMotion->GetFeedrateConstantValue (FeedrateValue,Ratio,i))

{

if (NULL_var != FeedrateValue)

{

String1 = "++++++ Feedrate value";

String1.Resize(60);

String1 = String1 + FeedrateValue->Show();

WriteString (iLevel,String1);

ValueX.BuildFromNum (Ratio);

String1 = "++++++ Ratio to apply on feedrate";

String1.Resize(60);

String1 = String1 + ValueX;

WriteString (iLevel,String1);

}

}

//================================

// Special test for RAPID Feedrate

//================================

else if (iMultipleMotion->GetFeedrate (Feedrate,Ratio,i) &&

TPRapidFeedrate == Feedrate)

{

String1 = "++++++ RAPID feedrate for the motion";

WriteString (iLevel,String1);

}

}

//=================================================

// Retrieves spindle speed value for the sub-motion

// --> For a polyline or a circle arc

//=================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

CATICkeParm_var SpindleValue;

double Ratio;

if (iMultipleMotion->GetSpindleConstantValue (SpindleValue,Ratio,i))

{

if (NULL_var != SpindleValue)

{

String1 = "++++++ Spindle value";

String1.Resize(60);

String1 = String1 + SpindleValue->Show();

WriteString (iLevel,String1);

ValueX.BuildFromNum (Ratio);

String1 = "++++++ Ratio to apply on spindle";

String1.Resize(60);

String1 = String1 + ValueX;

WriteString (iLevel,String1);

}

}

}

//======================================================

// Retrieves spindle rotation direction for a sub-motion

// --> For a polyline or a circle arc

//======================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

int RotationWay;

if (iMultipleMotion->GetSpindleRotationWay (RotationWay,i))

{

if (-1 == RotationWay)

{

String1 = "++++++ Inverse rotation direction for the spindle";

WriteString (iLevel,String1);

}

else

{

String1 = "++++++ Normal rotation direction for the spindle";

WriteString (iLevel,String1);

}

}

}

//====================================================

// Retrieves tool axis for the sub-motion

// --> For a polyline or a circle arc

// --> If fixed for the sub-motion

//====================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

CATMathVector ToolAxis;

if (iMultipleMotion->GetToolAxisConstantValue (ToolAxis,i))

{

ValueX.BuildFromNum (ToolAxis.GetX());

ValueY.BuildFromNum (ToolAxis.GetY());

ValueZ.BuildFromNum (ToolAxis.GetZ());

String1 = "++++++ Fixed Tool Axis value";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String1);

}

}

//====================================================

// Retrieves characteristics if sub-motion is a circle

// --> Normal vector to the plane containing the circle

// --> Center of the circle arc

// --> Radius of the circle arc

// --> Angle of the circle arc

// --> Tangent vector at the start of the circle

//====================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

CATMathVector Normal,StartTangent;

CATMathPoint Center;

double Radius;

CATAngle Angle;

if (iMultipleMotion->GetCircleCharacteristics (i,

Normal,Center,Radius,Angle,StartTangent))

{

ValueX.BuildFromNum (Normal.GetX());

ValueY.BuildFromNum (Normal.GetY());

ValueZ.BuildFromNum (Normal.GetZ());

String1 = "++++++ Normal to the plane ";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String1);

ValueX.BuildFromNum (Center.GetX());

ValueY.BuildFromNum (Center.GetY());

ValueZ.BuildFromNum (Center.GetZ());

String1 = "++++++ Center of the circle arc";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String1);

ValueX.BuildFromNum (Radius);

String1 = "++++++ Radius of the circle arc";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String1);

ValueX.BuildFromNum (Angle);

String1 = "++++++ Angle of the circle arc";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String1);

ValueX.BuildFromNum (StartTangent.GetX());

ValueY.BuildFromNum (StartTangent.GetY());

ValueZ.BuildFromNum (StartTangent.GetZ());

String1 = "++++++ Tangent at the start of the circle arc";

String1.Resize(60);

String1 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String1);

}

}

//======================================

// Retrieves tool corrector number value

// --> For a polyline or a circle arc

//======================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PolyLine ||

SubTrajectType == CATIMfgTPMultipleMotion::Circle)

{

int CorrectorNumber;

if (iMultipleMotion->GetCorrectorNumber (CorrectorNumber,i))

{

ValueX.BuildFromNum (CorrectorNumber);

String1 = "++++++ Tool corrector number";

String1.Resize(60);

String1 = String1 + ValueX;

WriteString (iLevel,String1);

}

}

//=======================================================

// Retrieves evaluation of a NC_Command or NC_Instruction

//=======================================================

if (SubTrajectType == CATIMfgTPMultipleMotion::PPCommand)

{

CATListValCATUnicodeString CommandValue;

if (iMultipleMotion->GetCommandEvaluation (i,CommandValue))

{

int NumberOfValue = CommandValue.Size();

for (int j=1;j<=NumberOfValue;j++)

{

String1 = "++++++ NC_Command value";

String1.Resize(60);

String1 = String1 + CommandValue[j];

WriteString (iLevel,String1);

}

}

}

}

}

|

The CATIMfgTPMultipleMotion interface is useful to modelize the tool motions.

It can describe several tool motions which can be the following types:

The sample illustrates the use of the following methods:

GetNumberOfTipPoints: retrieves the total number of tip

points for all "polylines" and circle arcs of the CATIMfgTPMultipleMotion

objectGetNumberOfContactPoints, GetNumberOfContactNormals,

GetNumberOfToolAxisPoints: retrieve respectively the number of

contact points, the number of contact normals, the number of tool axisGetTipPoint: retrieves coordinates of a tip point (with an

index between 1 and the total number of tip points retrieved by GetNumberOfTipPoints)GetNumberOfSubTrajects: retrieves the total number of

sub-motions ("polyline", Circle Arc, PPCommand (NC_Command or

NC_Instruction), User Syntax)GetToolAssembly: retrieves the tool or tool assemblyGetSubTrajectType: retrieves the type ("polyline",

CircleArc, PPCommand (NC_Command or NC_Instruction), User Syntax) of a

given sub-motionGetTrajectType: retrieves the mode of work of the tool

("MachiningTraject","ApproachTraject", ....) of a

given sub-motionGetStartAndEndNumber: retrieves index of first and last tip

point for a given sub-motionGetStartAndEndNumberGetFeedrateConstantValue: retrieves the value of feedrate for

a given sub-motionGetSpindleConstantValue: retrieves the value of spindle speed

for a given sub-motionGetSpindleRotationWay: retrieves the way of rotation of the

spindle for a given sub-motionGetToolAxisConstantValue: retrieves the value of tool axis for

a given sub-motionGetCircleCharacteristics: retrieves the specific

characteristics if the given sub-motion is a circle arcGetCorrectorNumber: retrieves the tool corrector number of

a given sub-motionGetCommandEvaluation: retrieves the evaluation of the syntax if

the given sub-motion is a PP Command (NC_Command or NC_Instruction).

//==================================

// DumpMultipleMotionWithProfileData

//==================================

void CAAMaiDumpToolPathCommand::DumpMultipleMotionWithProfileData (int iLevel,

const CATIMfgTPMultipleMotionWithProfileData_var& iMultipleMotionWithProfileData)

{

//=============================================================================================

// As a CATIMfgTPMultipleMotionWithProfileData object is also a CATIMfgTPMultipleMotion object,

// dump of its "CATIMfgTPMultipleMotion" attributes

//=============================================================================================

DumpMultipleMotion (iLevel,iMultipleMotionWithProfileData);

//=========================================================================================

// Now we dump the specific attributes of the CATIMfgTPMultipleMotionWithProfileData object

//=========================================================================================

CATUnicodeString text1;

text1.Resize(60,'=');

WriteString (iLevel,text1);

CATUnicodeString String = "+++ Dump of cutter profile datas ";

WriteString (iLevel,String);

WriteString (iLevel,text1);

int number;

iMultipleMotionWithProfileData->GetNumberOfSubTrajects (number);

for (int i=1;i<=number;i++)

{

CATUnicodeString Index;

Index.BuildFromNum (i);

CATIMfgTPMultipleMotionWithProfileData::ProfileType ProfileType;

if (iMultipleMotionWithProfileData->GetProfileType (i,ProfileType))

{

if (ProfileType == CATIMfgTPMultipleMotionWithProfileData::UndefType)

{

CATUnicodeString String = "+++ No cutter profile datas for sub-motion "+Index;

WriteString (iLevel,String);

}

else if (ProfileType == CATIMfgTPMultipleMotionWithProfileData::Polyline)

{

CATUnicodeString String = "+++ Cutter profile datas described by a polyline for sub-motion "+Index;

WriteString (iLevel,String);

}

else if (ProfileType == CATIMfgTPMultipleMotionWithProfileData::Circle)

{

CATUnicodeString String = "+++ Cutter profile datas described by a circle for sub-motion "+Index;

WriteString (iLevel,String);

}

}

CATIMfgTPMultipleMotionWithProfileData::ProfileSide ProfileSide;

if (iMultipleMotionWithProfileData->GetProfileSide (i,ProfileSide))

{

if (ProfileSide == CATIMfgTPMultipleMotionWithProfileData::UndefType)

{

CATUnicodeString String = "+++ No cutter profile datas for sub-motion "+Index;

WriteString (iLevel,String);

}

else if (ProfileSide == CATIMfgTPMultipleMotionWithProfileData::Left)

{

CATUnicodeString String = "+++ Cutter profile datas located on the left for sub-motion "+Index;

WriteString (iLevel,String);

}

else if (ProfileSide == CATIMfgTPMultipleMotionWithProfileData::Right)

{

CATUnicodeString String = "+++ Cutter profile datas located on the right for sub-motion "+Index;

WriteString (iLevel,String);

}

}

int NumberOfProfilePoints;

if (iMultipleMotionWithProfileData->GetNumberOfProfilePoints (i,NumberOfProfilePoints))

{

Index.BuildFromNum (NumberOfProfilePoints);

CATUnicodeString String = "+++ Number of cutter profile points "+Index;

CATUnicodeString ValueX,ValueY,ValueZ;

CATUnicodeString String1,String2;

double x,y,z;

for (int j=1;j<=NumberOfProfilePoints;j++)

{

if (iMultipleMotionWithProfileData->GetProfilePoint (i,j,x,y,z))

{

ValueX.BuildFromNum (x);

ValueY.BuildFromNum (y);

ValueZ.BuildFromNum (z);

Index.BuildFromNum (j);

String1 = "Profile point number "+Index;

String1.Resize(60);

String2 = String1 + ValueX + " " + ValueY + " " + ValueZ;

WriteString (iLevel,String2);

}

}

}

}

}

|

The CATIMfgTPMultipleMotionWithProfileData interface inherits from the CATIMfgTPMultipleMotion interface.

As the object with implements the CATIMfgTPMultipleMotion interface, the object with implements the CATIMfgTPMultipleMotionWithProfileData interface allows to model tool motions.

It can contain several sub-motions of the following type:

Specifically to the object which implements the CATIMfgTPMultipleMotionWithProfileData interface, it is possible to add cutter profile data on each tip sub-motion.

To model these cutter profile data, you can use either a "polyline", or a circle arc.

The sample illustrates the use of the following methods:

GetProfileType : retrieves the type of cutter profile data

associated to a tip sub-motion (none, "polyline",circle arc)GetProfileSide : retrieves the side on which are located

cutter profile data (none, right, left).GetNumberOfProfilePoints: retrieves the total number of

cutter profile points for a tip sub-motionGetProfilePoint: retrieves the coordinates of a cutter

profile point.Methods to retrieve characteristics of cutter profile data described by a circle arc exist also.

This article provides an example on how to use the ManufacturingInterfaces classes to read data of the tool path of an operation , and has illustrated them on an interactive command to dump the tool path linked to a manufacturing operation.

| [1] | Building and Launching a CAA V5 Use Case |

| [2] | Process Modeler Home Page |

| Version: 1 [Nov 2001] | Document created |

Copyright © 2001, Dassault Systèmes. All rights reserved.